By Jim Smart

A lot of performance promises have been made since the advent of the internal combustion engine more than a century ago: miracle lubricants, gasoline additives, new-fangled carburetors, fire-injector spark plugs, and a host of other miracle paths to power, each with its own disappointments.

But there are no free lunches in the world of high-performance engines. Engines are mostly about physics, math, and the process of turning heat energy into mechanical motion. So how to get more twist from that heat energy and rotary monkey motion? We’ve got 10 quick and easy ways to increase your car’s horsepower and engine performance. Do be sure that all work is done properly and that it doesn’t void your manufacturer’s warranty.

1. Synthetic lubricants

Because synthetic lubricants, such as Mobil 1™ synthetic motor oils, reduce friction, they help engines live longer. Synthetic lubricants create better lubrication between moving parts than conventional oils do. They don’t break down in high-heat, high-stress situations, which is why you see them used a lot in performance applications. They also offer excellent cold weather performance and extreme temperature protection. For example, Mobil 1 synthetic oil is engineered to be more robust in terms of low-temperature pumpability, high-temperature stability and protection against deposits.

2. Ignition

Because ignition systems have become low maintenance in the past 20 years, we don’t check them until we get a misfire and a "Check Engine" light. The fact remains, car maintenance still should include ignition systems. And spark plugs still need to be changed periodically. When it’s time to replace ignition components, opt for the best high-performance ignition parts you can find, meaning coils, ignition wires and platinum tip spark plugs.

Original equipment grade is your best approach or high-end aftermarket parts like MSD. The reason: precision ignition operation means power. A misfire or lackluster light off means lost power, wasted fuel and increased tailpipe emissions. A potent spark from a high-energy ignition system does make a difference in power no matter how small. The lesson here is it all adds up to significant total gains in horsepower.

Ignition timing is also a power dynamic you should play with carefully because too much of it can damage your engine. With conventional distributor ignition systems, set total timing at 2500 rpm beginning your efforts at 32 degrees BTDC (Before Top-Dead Center) with a road test or dyno pull. Then, move timing one degree at a time – 33, 34, 35 and so on along with road/dyno testing. Never take total timing beyond 36 degrees BTDC.

Some tuners go to 38, 40, and even 42 degrees BTDC, which is foolish. Anything beyond 36 degrees BTDC total represents risks due to detonation. If you have a sudden lean condition coupled with early timing, you can have engine failure in a nanosecond at wide-open throttle. Ignition timing with electronic engine control calls for a professional who knows how to dial in both ignition and fuel maps to where you get power without doing engine damage.

3. Larger throttle body and injectors

A larger high-performance throttle body will deliver more horsepower. Depending on what type of engine you have, you can gain as much as 10-20 more horsepower and comparable torque. There is a catch, however. Go too large and you can lose power. Not every engine is well suited to a larger throttle body, which means you have to do your homework ahead of time. Cruise the internet and learn what others with the same engine are doing and take your lead from them. Also remember that a larger throttle requires higher-flow fuel injectors. Throttle body and injector size are proportional. You should also take your car to a reputable dyno tuner to make adjustments to fuel and spark curves, which fine-tunes your throttle body/injector upgrade.

4. Compression

Increasing compression is the most productive way to increase horsepower. Build compression into your engine and you build in power. In more than a century of internal combustion, there has never been a more common sense way to make power. But be careful about how you raise compression. Compression and cam selection go hand in hand because cam selection also affects cylinder pressure or working compression.

Your engine builder can best advise you on compression and cam selection. Both have to be chosen in a spirit of cooperation, so you get power without damaging your engine. Compression beyond 10.0:1 these days can cause detonation, spark knock, pre-ignition, or what is also known as “pinging” if you don’t have enough octane. Watch fuel and spark curves while you are bumping compression. And remember, pump gas isn’t what it used be. However, high octane, smog-legal unleaded fuel is available in five-gallon cans if you have the budget for it.

5. Found-bonus power

Think about this for a minute: Your engine actually produces more power than it delivers. Consider the power lost to internal friction, components that consume untold amounts of power just to move them. And consider how much heat energy is lost to the atmosphere that does nothing for power. Did you know your engine wastes 70-75 percent of the heat energy generated from fuel/air light off? Fifty percent out the tailpipe and 25 percent via the cooling system. This means we harness barely 25 percent of the fuel’s BTUs (British Thermal Units). Talk about waste. It’s insulting to efficiency experts everywhere.

So how to reduce friction and free up power?

- Roller tappet camshaft

- Roller rocker arms

- Dual-roller timing set

- Needle-bearing cam sprocket

- Low tension piston rings

- Greater piston-to-cylinder wall clearances (within limits)

- Greater bearing clearances (within limits)

- Greater valve-to-guide clearances (within limits)

- Windage tray (oil windage at high rpm robs power)

Keep in mind that it’s always a tradeoff. When you go with low-friction components like roller tappets and rocker arms, you gain, but you also spend. Low-tension piston rings and more liberal clearances mean some sacrifice of durability.

How much of your car’s driveline robs you of power? And though it may sound like an old saw, tire inflation and tire/wheel sizing are also factors in sluggishness. The greater your car’s contact patch, the more power it takes to move. Underinflated tires will make your car feel like it’s chained to a tree under hard acceleration. Take tire inflation right to the tire’s limits, depending upon ambient temperature. Temperature directly affects pressure.

6. Velocity stack

A velocity stack is a trumpet-shaped device that is fitted to the air entry of an engine’s intake system, carburetor or fuel injection and improves airflow. The product reduces induction turbulence, which is why you can expect an increase in horsepower.

7. Fuel line right-sizing

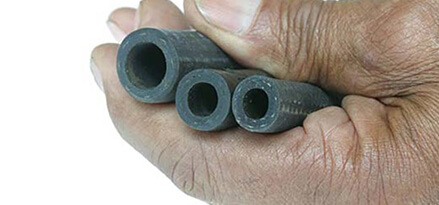

You might laugh, but you’d be surprised how often we get this one wrong. You’re not going to get 450 horsepower from a 5/16-inch fuel line. Think of it as trying to rapidly draw iced tea through a cocktail straw. You’re going to come up short. High-performance engines need fuel and plenty of it. Minimum fuel line size should be 3/8-inch for most applications. When horsepower rises above 500, you need 7/16-inch fuel line.

8. Dual-plane manifold

Here’s another one that performance enthusiasts get wrong more times than not. While we’re so busy paying attention to horsepower, we forget to acknowledge torque. Torque is your buddy on the street, not horsepower. You want torque to hand off smoothly to horsepower at wide-open throttle. However, you won’t get there smoothly with a single-plane intake manifold.

A dual-plane intake manifold offers great low- to mid-range torque while also allowing an engine to breathe at high rpm. This means greater torque numbers during acceleration and higher horsepower figures on top. It’s the dual-plane manifold’s long intake runners that give you torque, and high ceilings that deliver horsepower. One more thing: Consider the use of a carburetor spacer to get even more torque out of a traffic light

9. Experiment with jet size

We’ve learned time and time again in dyno testing that jet swaps can go either way when it comes to power. Too much or too little can mean power losses, which is why it’s suggested you pick up a Holley jet kit and do a little experimenting. Go up one jet size at a time and see what you get, beginning first with primaries, then secondaries. Always better to err on the side of richer than leaner. If you lose power as you go richer, start going backward one jet size at a time. Go with a spark plug reading while you’re at it right after a wide-open throttle shutdown to determine course of action.

If you’re running a carburetor with a fuel line screen at the fuel bowl, remove it while you’re in there. An in-line fuel filter is plenty enough and won’t hinder fuel supply.

10. Cylinder head

There was a time when cylinder head selection was decidedly modest for those wondering how to increase engine performance. Today, selection is downright sinful. A good cylinder head swap will get you more power if you go about it correctly. Bigger doesn’t always mean better. Look at valve and port size along with flow numbers to make an educated decision.

Remember, you want torque on the street, which calls for good intake velocity coupled with compatible exhaust scavenging. You don’t need huge valves and monster ports to get there. You also want a camshaft profile that works well with the cylinder heads, meaning good overlap and nice flow-through momentum.