Paul Grives, Global Services & Grease Marketing Manager, ExxonMobil Fuels & Lubricants

Some customers think grease selection can be complicated and confusing, but it doesn’t have to be.

Let me try to demystify grease a bit.

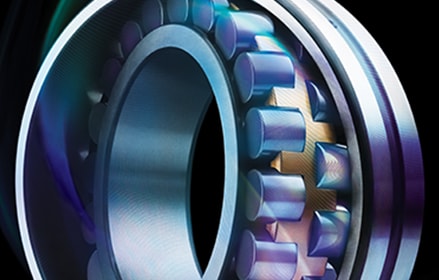

Different types of greases are typically formulated with three grease components: base oil, thickener and additives.

- The base oil lubricates, reducing friction between moving surfaces; this is exactly the same role that the base oil plays in a lubricant oil.

- The thickener acts like a sponge; its job is to hold oil in reserve until needed to lubricate. The thickener responds to external forces such as movement, vibration or temperature as a trigger to release oil.

- The additives supplement the lubricating capability of the base oil, improving upon characteristics such as wear protection and rust prevention.

I’m frequently asked if synthetic oil-based greases are really better than mineral oil-based greases.

The short answer is YES.

While conventional, mineral oil-based greases can be formulated to deliver effective performance for many applications, synthetics typically deliver significant advantages, including extended oil life. Synthetic fluids provide superior lubricating capability across a much wider application temperature range, all other things being equivalent. This is true for lubricant oils as well as greases.

In high temperature applications, synthetic oil thins out less than comparable mineral oil, providing greater protection by forming a thicker oil film between surfaces. Additionally, these oils are less prone to degradation at elevated temperatures – a phenomenon called oxidation. Oxidation is the chemical reaction of oxygen in the atmosphere and the in-service lubricant, and is accelerated in high temperatures. Generally, the speed of oxidation doubles for every 10°C above 120°C.

At low temperatures, synthetic oil outperforms mineral oil by maintaining proper viscosity and better fluidity than mineral oil. Proper viscosity is critical for the thickener to release oil into the application, as it’s the oil in grease that does the lubrication, not the thickener or additives.

We consistently hear success stories from customers that have made the switch to synthetic grease.

From extending regreasing intervals at a plant from weekly to quarterly, to extending the life of machine bearings, synthetic grease can improve industrial operations and help to cut costs for operators.

Many companies are missing an opportunity to save big using the latest advances in grease science. Mobil Serv℠ Lubricant Analysis (MSLA) delivers a full spectrum analysis of your current lubricants, which no other service can provide.

MSLA collects crucial information vital in assessing the health of your operation including, but not limited to:

- Productivity

- Unscheduled downtime

- Equipment durability

- Lubricant consumption

- Safety

- Environmental care

Designed to help save time and money, MSLA helps operators manage their grease analysis faster —in fact, 66 percent faster than paper-based alternatives—making it one of the top choices on the market.

Sign up for a free trial today to see how MSLA can help your business.