Mobil Pegasus™ 1005 helps Argentinian oil and gas producer enhance equipment reliability*

Customer annual savings of

US $350,000

Situation

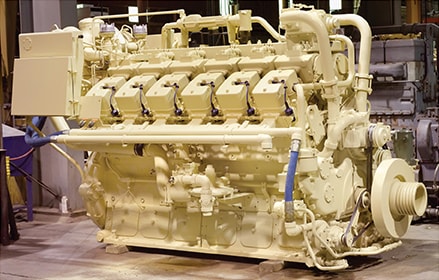

An Argentinian oil and gas producer operates more than 300 pieces of equipment, including gas compression, power generation and pump equipment from Waukesha, Caterpillar, Guascor, Ariel and Frick. With logistics, planned maintenance and environmental protection key components of its business, the company approached ExxonMobil engineers for a lubricant solution capable of enhancing equipment reliability and increasing productivity.

Recommendation

Using ExxonMobil’s Planned Engineering Services, the company worked with ExxonMobil engineers to identify mutual goals, which included upgrading to Mobil Pegasus™ 1005 natural gas engine oil, surveying lubrication points and lubricant recommendations. ExxonMobil engineers also recommended implementing Mobil ServSM Lubricant Analysis to monitor the condition of the in-service equipment and lubricants. Robust distribution and logistics were also put into place to supply more than 200 lubricant storage points throughout the oil and gas producer’s network.

Result

After following the recommendations of ExxonMobil engineers, the company reported fewer unplanned shutdowns, increased runtime between overhauls, and a decrease in oil, filter and spare parts consumption. In addition, upgrading to Mobil Pegasus™ 1005 natural gas engine oil has helped the company double oil drain intervals, reduce lubricant purchases and lower maintenance expenses, generating a company-estimated annual savings of US $350,000.

*This proof of performance is based on the experience of a single customer. Actual results can vary depending upon the type of equipment used and its maintenance, operating conditions and environment, and any prior lubricant used.