Mobil Pegasus 1005 helps gas compression plant double oil drain intervals*

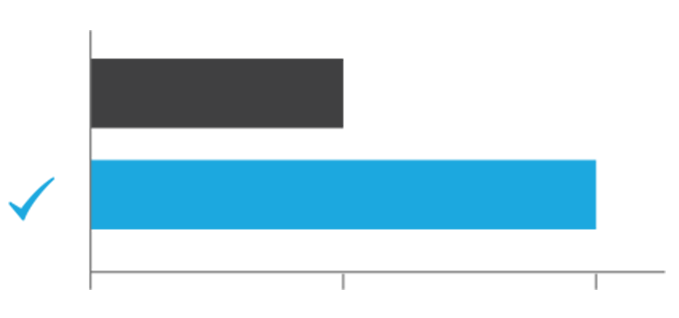

Oil drain intervals increased by

100%

CAT 3612 gas engines

Gas compression plant

Tartagal, Salta, Argentina

Situation

An Argentinian gas compression plant operates a fleet of six CAT 3612 engines, and maintained oil drain intervals of 5,000 hours with a previous lubricant. Maintenance personnel were pleased with engine performance, and a borescopic inspection found that the engine components were in good condition. Plant managers approached ExxonMobil to determine ways to further extend oil drain intervals and enhance engine performance.

Recommendation

ExxonMobil engineers recommended transitioning the six engines to Mobil Pegasus™ 1005, a natural gas engine oil formulated with premium basestocks and advanced additive technology, and designed to provide the highest level of protection while maintaining exceptional engine performance. Engineers also recommended implementing routine ExxonMobil’s Mobil Serv Lubricant Analysis (MSLA) and borescopic inspections to monitor condition of the engine’s components and in-service lubricant.

Benefit

After transitioning to Mobil Pegasus 1005 natural gas engine oil, maintenance personnel successfully doubled oil drain intervals from 5,000 hours to 10,000 hours. ExxonMobil’s Mobil Serv Lubricant Analysis (MSLA) also revealed diminished levels of oxidation and nitration, while borescopic inspections confirmed there were no deposits of varnish, lacquer or carbon residue on the various engine components. The extended oil drain intervals and reduced oil consumption generated an annual savings of US$53,700.

The product performance of Mobil Pegasus 1005, alongside the application expertise provided by local ExxonMobil engineering support and ExxonMobil’s Mobil Serv Lubricant Analysis (MSLA), is helping to improve customer productivity potential.

*This proof of performance is based on the experience of a single customer. Actual results can vary depending upon the type of equipment used and its maintenance, operating conditions and environment, and any prior lubricant used.

** Visit mobilindustrial.com to learn how certain Mobil-branded lubricants may provide benefits to help reduce environmental impact. Actual benefits will depend upon product selected, operating conditions and applications.

- Format :

- 352 kb PDF in English

- Posted :

- 10/1/2018