By Alan Suan

Virtually any piece of industrial equipment is vulnerable to corrosion, and when not appropriately managed, corrosion can lead to unplanned equipment downtime, reduced performance and higher maintenance costs.

Corrosion’s toll on U.S. heavy industry is staggering. In fact, according to ASM International, the cost of corrosion in the United States equates to approximately 4 percent gross national product.

Lubrication is key to preventing corrosion

One of the fundamental ways to mitigate corrosion – both when equipment is in service and out of service – is through proper lubrication.

With that in mind, let’s take a look at a few ways in which having the right lubrication strategy can help you combat corrosion.

Combating corrosion when your equipment is in service

When equipment is in service, your lubricant is the first line of defense against corrosion. And, the best lubricants are those with a balanced formulation, or that have the right mix of advanced base oils and a robust additive package.

Additives – specifically corrosion inhibitors – can help protect against humidity, water contamination, and high temperatures, which are among the leading causes of corrosion.

But, mere presence of the additive alone is not enough. You must ensure that the lubricant used is formulated with just the right amount of corrosion inhibitor. If a formulation has too high or too low a percentage of the additive, the inhibitor could become less effective in mitigating corrosion.

Second, you want to make sure that these anti-corrosion benefits come without any sacrifice in overall lubricant performance, why is why it’s important to select lubricants with a balanced formulation.

In addition to corrosion resistance, you want to measure a lubricant’s quality based on its viscosity, wear resistance, and oxidation stability, among other characteristics.

A lubricant’s performance across these characteristics is influenced by the types and ratios of base oils and additives used. Work closely with your lubricant supplier to understand the formulation of your industrial lubricants and select lubricants that are formulated to perform well across a range of parameters, including corrosion resistance.

Protecting your equipment when not in service

Equipment is also prone to corrosion even when it’s not running. For example, if your equipment is stored in hot and humid conditions, it can be more vulnerable to corrosion.

Properly preparing equipment for storage can make a meaningful difference in performance down the road, as incorrect storage procedures can lead to component damage.

Depending on the type of equipment, precautionary measures can involve lubrication, specifically grease.

Many greases are formulated with robust anti-corrosion additives, and application of these lubricants before storage can help protect equipment from hot, humid, and/or damp environments.

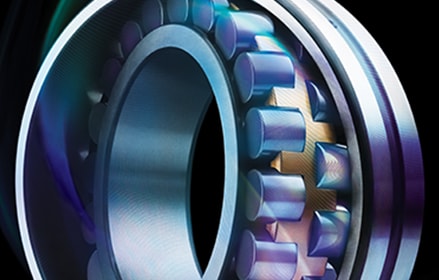

For example, let’s look at roller bearings, which are commonly found in many industrial plants today. The failure of a single bearing can cause significant losses in production, so it’s critical to protect them against rust even when in storage.

To properly prepare these bearings for storage, they are first pumped with a rust-preventative grease between twelve and twenty-four hours prior to equipment shutdown. Maintenance personnel typically use a high quality, synthetic grease to help prevent rusting over several days.

As soon as the rolls are placed in storage, they then remove the pillow block housings and take out the old grease before injecting outer rings with new grease and coating the internal surfaces of the pillow block halves.

Once all foreign matter is removed from the grease fittings, maintenance personnel then inject rust-preventative grease into the fittings while rotating the roll to ensure maximum distribution of the lubricant. Each mounted pillow block is then secured with a heavy polyethylene sack or similar watertight material before put away for storage. When the rolls are stored, they are rotated at least once per week to keep any moisture from setting at the bottom.

As the above example demonstrates, it’s important to also consider lubrication when keeping equipment in storage, as it is a critical part of any storage best practice.

Partner with your lubricant supplier

While you may already have a robust preventative maintenance approach, hopefully this article has helped shine a light on the central role of lubrication in mitigating corrosion across the equipment lifecycle.

By taking the right precautionary measures, your equipment and components will continue to remain corrosion-free, providing you with the best chance to maximize productivity after reinstallation.

To learn what how you can optimize your lubrication program, talk to your lubricant supplier.