Emergency water and particulate removal

Without interrupting production, this emergency service helps minimize the potential for serious component damage resulting from a sudden contamination event.

Description

Field engineers use their world-class expertise to provide you with immediate support following a sudden ingress of water or other contaminants. Because high contaminant levels can severely compromise a lubricant’s ability to protect valuable assets, the service includes complete lubricant purification.

Application

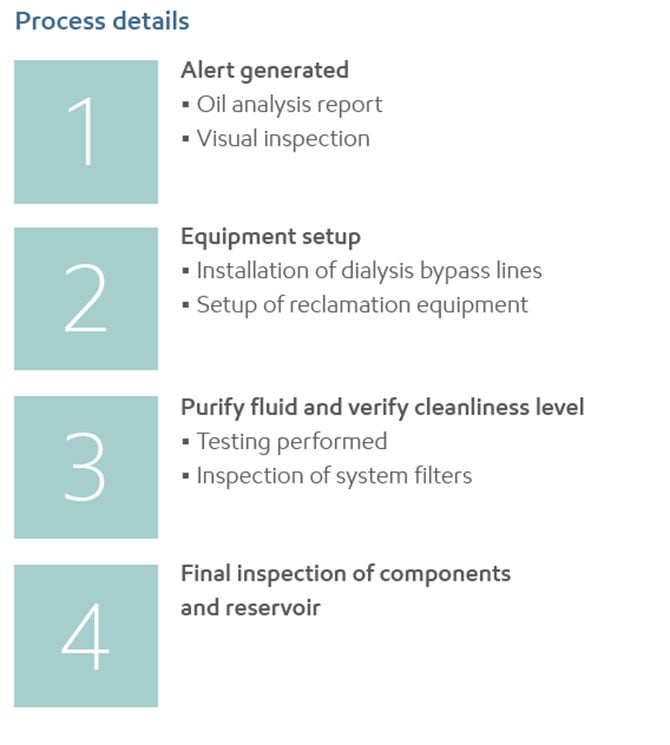

Expert engineers will work with you to:

- Coordinate proper response to the contamination event

- Determine the root cause for the event

- Assist in implementing a solution that might include regular oil system preventive maintenance

- Coordinate arrangements with the service technician who will:

- Complete the purification of the lubricant in the equipment

- Verify that lubricant cleanliness specifications are met or exceeded

- Offer reclamation equipment rental options for maintaining the restored cleanliness level

Deliverable: An Engineering Service Report details the lubricant treatment steps completed, documents lubricant cleanliness level prior to and after treatment, recommends steps to maintain lubricant system cleanliness and provides an estimated value of the service. Distribute and present the completed report to plant management and key personnel.

Common opportunity areas

- Elevated free water/condensation in system

- High contaminant levels

- Repetitive component failures due to lubricant contamination

- Oil that doesn’t meet manufacturer specifications

Safety, health and environment

Field engineers are attuned to the hazards of handling, storing and using petroleum products. They strictly observe safety and environmental rules and ExxonMobil and customer safety practices. They coordinate efforts through designated plant personnel verifying electrical and mechanical lockout and proper tagging prior to working on equipment, and providing recommendations to help reduce hazards.