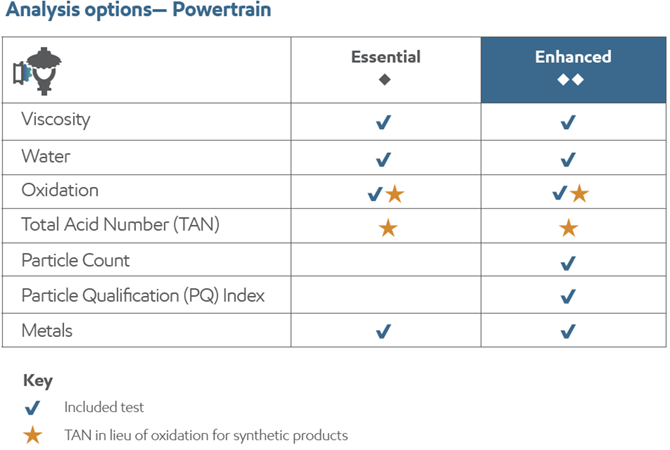

Powertrain analysis

This service monitors transmission, differential and final drive oils for premature wear, contamination and oil condition

Description

Powertrain analysis helps detect gear or transmission problems and lubricant contamination before they can result in costly downtime or repairs. The analysis is applicable to transmission, differential or final drive (gear) components in all types of mobile equipment, and includes testing to help you ensure long equipment life and optimal performance.

| Test | Purpose | Importance of test |

|---|---|---|

| Metals | To determine the presence and levels of metallic content in the oil, including contaminants and wear particles | The level of metals helps determine if equipment components are wearing or if harmful contamination is entering the oil. The level of metals that are part of the additive chemistry are also reported |

| Oxidation | To determine the level of lubricant oxidation and deterioration |

Oxidation can mean:

|

| Particle Count Analysis | To measure the level of particulate contaminants in the oil |

|

| Total Acid Number (TAN) | To measure acidic oil oxidation by-products | An elevated Total Acid Number may indicate increased oil acidity resulting from increased oil oxidation |

| Viscosity | To determine the oil’s resistance to flow |

|

| Particle Qualification (PQ) Index | To determine ferrous metal fatigue failures and metal-to-metal contact not usually detectable with some spectrographic analysis |

PQ Index can detect at an early stage:

|

| Water | To detect presence of water contamination | Water contamination may cause severe corrosion and subsequent wear, poor oil film thickness or hydrogen embrittlement |